Process chillers are much diverse than HVAC chillers and their programs are somewhat various also. Similarly, industrial process cooling is different in the way it operates too. Enable’s take a further explore how the process cooling process operates. Find out more regarding how chillers perform listed here.

For support figuring out the proper chiller for you, we endorse chatting by your preferences with our skilled group. With over thirty a long time of encounter in process cooling through the most demanding industries, we have been right here to help you.

Ingersoll Rand has developed reciprocating one stage air compressors and two stage air compressors to very last a life span — Thanks to rapid, uncomplicated maintenance with renewable elements. Quick access to the pump factors within our reciprocating compressors allows for routine routine maintenance and substitute of pieces much like the individually Solid cylinders, the piston put on-sleeves, plus the 15,000-hour bearings.

We understand how crucial it's to get your cooling procedure again up and functioning during the event of a procedure failure.

Our tension lubricated reciprocating compressors are intended to withstand even probably the most demanding industrial environments given that the reliable cast-iron development of the head, crankcase, cylinders, and deep-finned interior coolers facilitate longevity and dependability.

Utilise no cost cooling – make use of the reduced ambient air temperature, when achievable, to save on mechanical cooling, this helps your cooling equipment last for a longer get more info period much too as There may be a lot less use and tear on crucial components just like the compressor.

Although each web site was a bit distinctive in size and layout, our group made a process using indirect oil-fired heaters which could attain a comfortable 22˚C temperature in excess of the Winter season months. Examine the entire circumstance research

Our process cooling chillers with screw compressors have fuel-cooled motors, for much better Procedure and an integral lubricating system. These compressors have an incredibly large working temperature array.

Along with this we also offer absolutely free cooling and reduced GWP chillers as well as OEM and process chillers.

Process cooling chillers make a cycle that sends liquids throughout the procedure to transfer heat. A liquid attracts heat through the products and moves into your process cooling unit.

Our dual circuit electronic scroll h2o-cooled chiller alternatives can be found in models ranging from 8 to thirty HP. They are really engineered with the sector-main and lengthy-lasting Copeland scroll compressor with electronic technological know-how for precision temperature Manage and modulation right down to twenty% capability.

If your enterprise is seeking a cost-productive, ethical chiller process, choosing a chiller that has a Low World-wide Warming Potential refrigerant will give energy efficiency and price financial savings when reducing your carbon footprint.

Split process chillers function an out of doors air condenser, when the compressors are website located indoors with the chiller evaporator.

In combination with this we also supply no cost cooling and reduced GWP chillers and also OEM and process chillers.

Jurnee Smollett Then & Now!

Jurnee Smollett Then & Now! Kelly Le Brock Then & Now!

Kelly Le Brock Then & Now! Monica Lewinsky Then & Now!

Monica Lewinsky Then & Now! Tina Louise Then & Now!

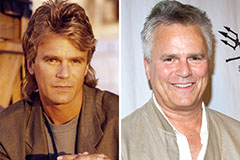

Tina Louise Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!